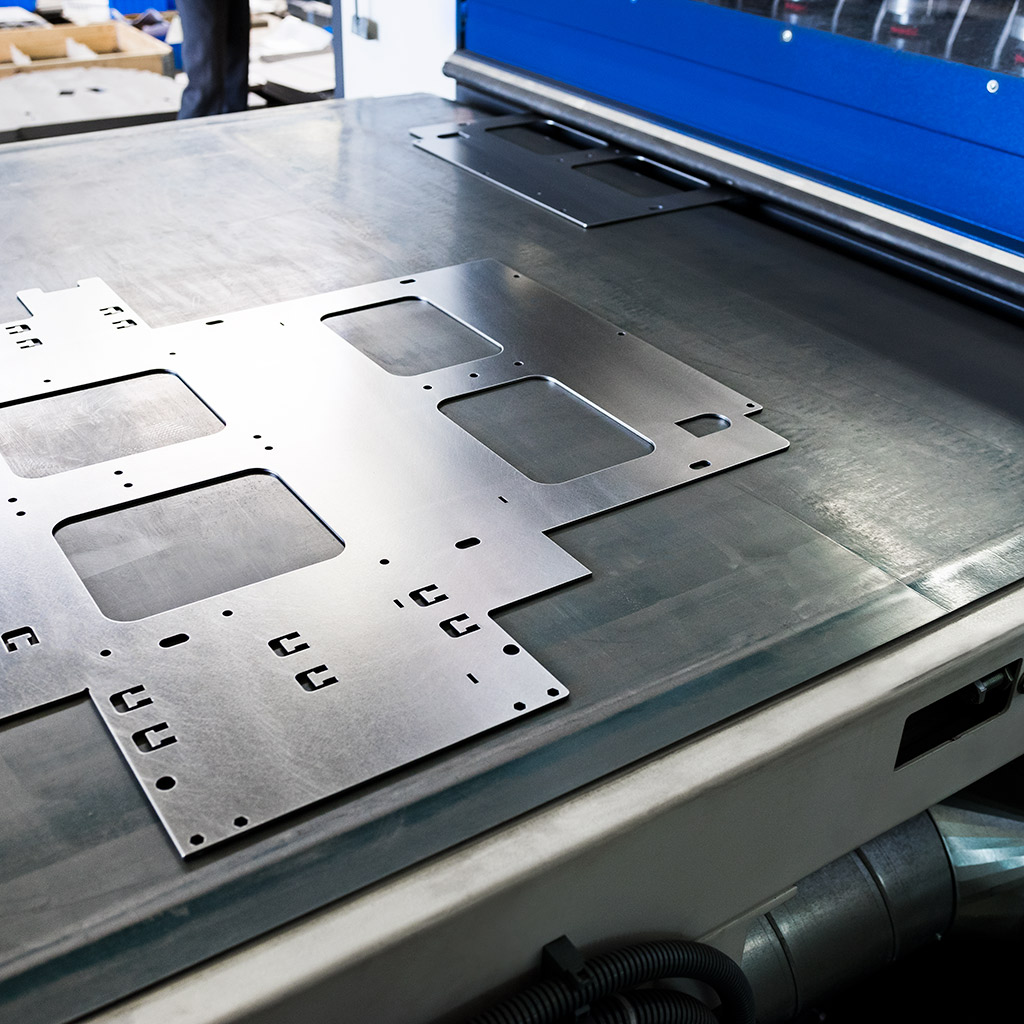

Sheet and tubular metal processing is dominated by laser cutting technologies.

Precision, manufacturing flexibility and material variety have made laser cutting an integral component of the industries processing land scape. WMT employs machinery from industry leader Trumpf. Our TruLaser units utilize state of the art fiber technology. Superior processing speeds, cutting power of up to 6kW and cutting abilities of 25mm for carbon steel, 20mm for stainless steel and 12mm for aluminium allow a wide range of applications. Both sheet metals and tubes can be processed with material sizes ranging up to 4000mm x 2000mm for sheets and a maximum diameter of 370mm and wall thicknesses of up to 10mm for tubes. Furthermore fiber technology allows the processing of non ferrous metals such as copper and brass.

We see ourselves as a holistic systems partner.

WMT is equally proficient in manufacturing fully engineered components and offers comprehensive design and development services creating individual parts or complex assemblies and devices. As development partner we work closely with our clients from a first idea all the way through to the final product. In this capacity, WMT can either operate as a support function or run the entire process delivering finalized components ready for internal or external production. Pick and pack services as well as logistics are equally part of our competencies and underline our motivation to not only be highly specialized but versatile at the same time. Knowing that individual needs vary greatly, WMT will tailor processes towards our clients ever changing objectives.

Water jet cutting is an ideal extension to laser cutting processes.

In addition to sheet metals water jet cutting is capable of processing a broad variety of materials such as ceramics, glass, stone, wood, rubber, reinforced plastics etc. WMT utilizes state of the art machinery from Bystronic. Our ByJet units can process material thicknesses of up to 200mm and special formats of 6000mm x 3000mm. In addition to material variety water jet cutting provides superior cutting results due to the fact that materials are not being affected thermically. This makes water jet cutting the ideal solution whenever the crystalline structure of the material needs to stay unaltered due to further processing

To guarantee perfect aesthetic and haptic results burrs that occur during cutting are securely removed throughout the manufacturing process.

In addition, WMT utilizes deburring machines from level and deburr specialist Arku. The achieved edge rounding has a substantial impact on the surface quality. In particular powder coating profits from this process due to the elimination of sharp corners which result in varying coating thicknesses.

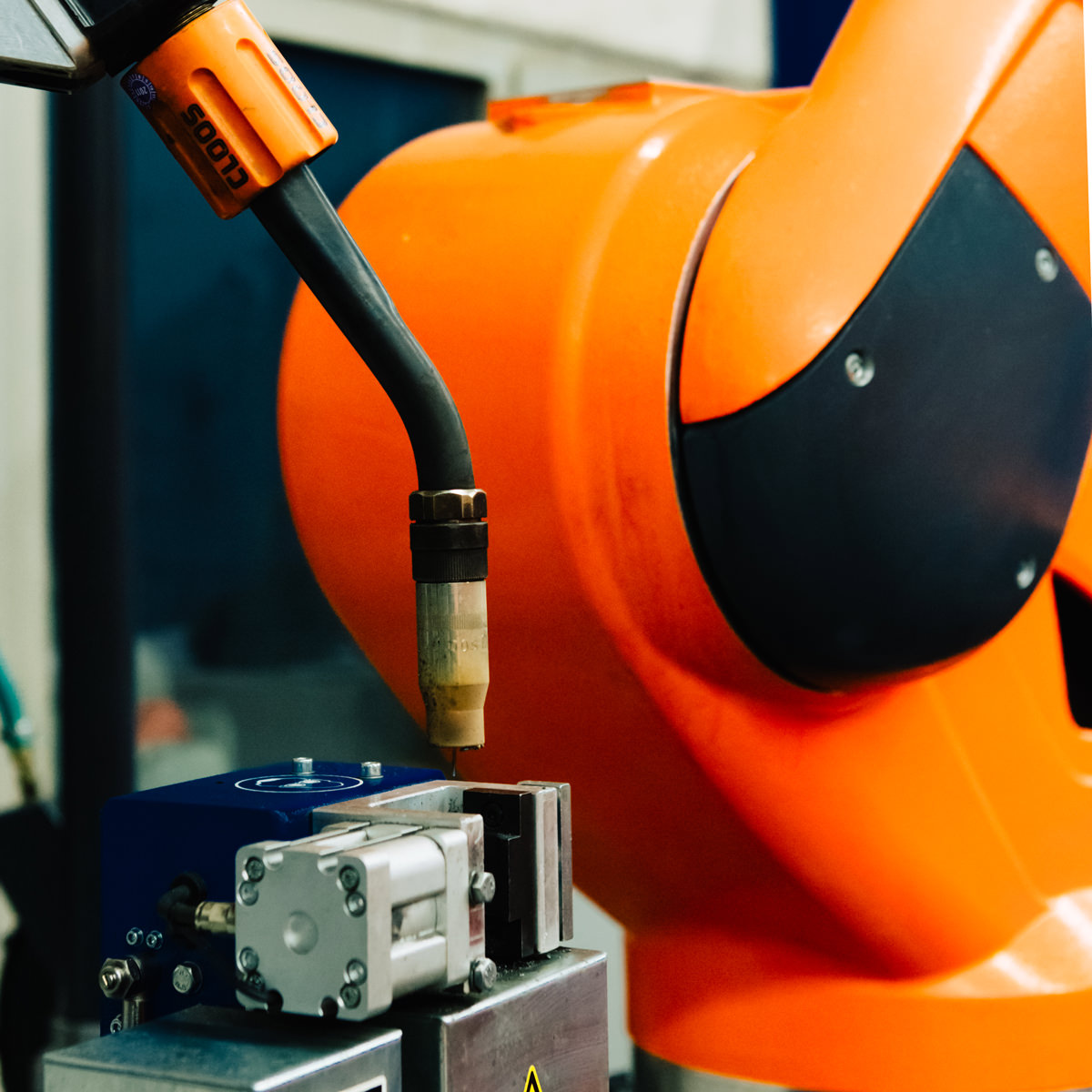

In addition to our well trained welding specialists and all established manual welding processes we utilize the latest robot welding technology from Cloos.

Automated welding is especially beneficial when it comes to high volume production runs. For this purpose individual tools are customized to match specific components which guarantees repetitive quality standards. Our machinery allows component sizes of up to 2000mm × 1100mm × 1100mm.

Components that have been precisely manufactured for this production step are being further processed on CNC-controlled mechanical press brakes which guarantee highest process reliability.

Advantages of this process are a near prefect distribution of force, no heat development and the continuous monitoring of angles during the bending process. WMT employs quality machinery from Trumpf – specifically Trubend units with a press force of up to 3200kN and a bending length of 4000mm which guarantee highest production precision and efficiency.

Material protection and surface finishing are just two attributes that make powder coating the ideal surface treatment in industrial metal processing.

Utmost coating quality and more efficient hence faster production processes are the reasons why WMT has established its own powder coating capabilities at our head quarters in Rottbitze.

WMT utilizes a modular Jumbo-Coat system from powder coating specialist Meeh. The unit consists of automated and manual components which allow uninterrupted in house processing. The facility is capable of processing parts up to 4000mm in length, 1000mm in height and 1500mm in width at a maximum weight of 1000kg.